gw204

Well-known member

So I'm not sure why I titled this thread "New Project...". Maybe it's just force of habit since the last two boats I bought were a '76 Forumla 233 and an '86 Grady 227, both with their share of "issues". Anyway, I went a different route this time and bought something that works.

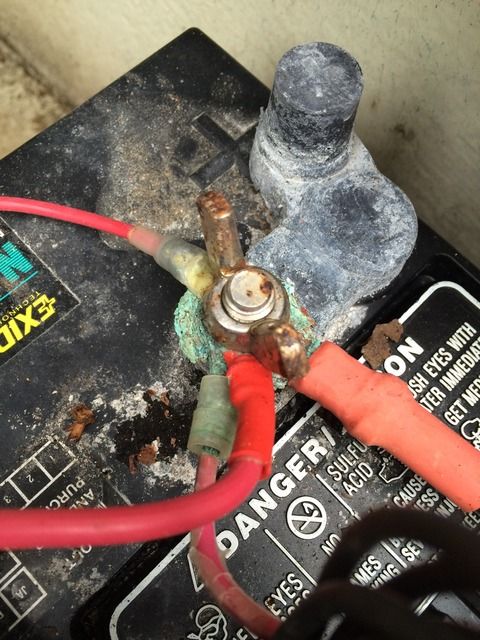

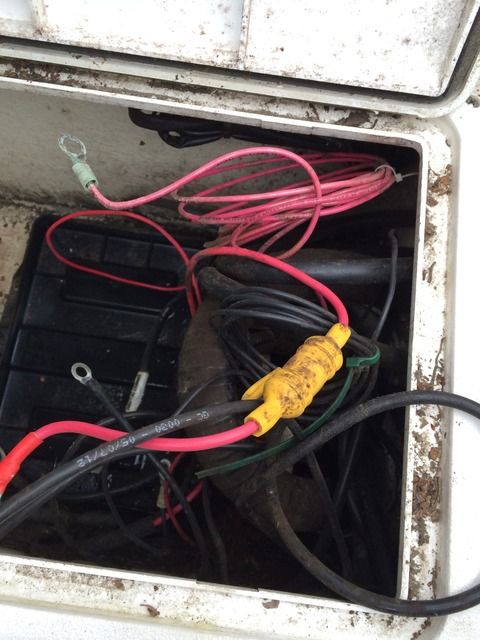

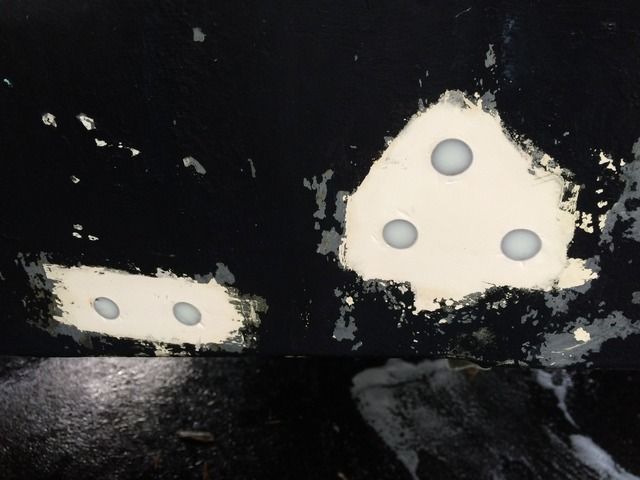

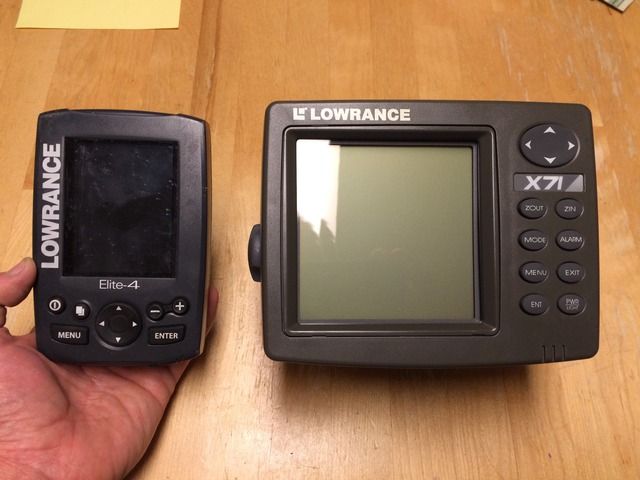

Introducing my new 2003 Maycraft 1800 skiff. She's powered by an '03 Merc 90 and sits on an '03 5-Starr trailer. Picked her up for a cool $3800. Overall, the boat seems very solid. Transom, floor and stringers all sounded very good. Only questionable things I found were some trailer rash on the keel, a fair amount of moisture and "snot" around the front of the fuel tank and a crack in one of the outside corners of the aft wells. None of which were enough to deter me from making the purchase.

Anyway, I will immediately admit that I have failed miserably with my initial photo documentation. After a quick stop for dinner at the Broadneck Grille, I got her home from the eastern shore of MD about 11 PM on Saturday. It was too chilly to do anything outside and I was beat...so I just hit the sack. The next morning my son was chomping at the bit to start "working" on her and any delay introduced by taking "as delivered" pictures was unacceptable. So we did a few little quick, easy things before I unleashed him with the soap and water. According to the seller, the boat had been sitting idle (covered) for 18 months but it was still filthy. So we emptied all of the stuff from the console and storage wells and I set about R&Ring the 3 deteriorating deck plates.

Popping them open revealed the boat's 42 gallon aluminum tank. With all the build up of grime on the plate sealing flanges, I'm not surprised they were leaking.

The boy and I cleaned the lids, o-rings and flanges thoroughly and got all the gunk up. I left them open for as long as I could to get some fresh air in there, lubed the rings with plumber's grease and screwed/popped the lids back on. I will replace all of them later this season, but for now this will do.

A hose, a bucket, some dish soap and an old car wash mit kept this little guy entertained for about 2 hours.

Introducing my new 2003 Maycraft 1800 skiff. She's powered by an '03 Merc 90 and sits on an '03 5-Starr trailer. Picked her up for a cool $3800. Overall, the boat seems very solid. Transom, floor and stringers all sounded very good. Only questionable things I found were some trailer rash on the keel, a fair amount of moisture and "snot" around the front of the fuel tank and a crack in one of the outside corners of the aft wells. None of which were enough to deter me from making the purchase.

Anyway, I will immediately admit that I have failed miserably with my initial photo documentation. After a quick stop for dinner at the Broadneck Grille, I got her home from the eastern shore of MD about 11 PM on Saturday. It was too chilly to do anything outside and I was beat...so I just hit the sack. The next morning my son was chomping at the bit to start "working" on her and any delay introduced by taking "as delivered" pictures was unacceptable. So we did a few little quick, easy things before I unleashed him with the soap and water. According to the seller, the boat had been sitting idle (covered) for 18 months but it was still filthy. So we emptied all of the stuff from the console and storage wells and I set about R&Ring the 3 deteriorating deck plates.

Popping them open revealed the boat's 42 gallon aluminum tank. With all the build up of grime on the plate sealing flanges, I'm not surprised they were leaking.

The boy and I cleaned the lids, o-rings and flanges thoroughly and got all the gunk up. I left them open for as long as I could to get some fresh air in there, lubed the rings with plumber's grease and screwed/popped the lids back on. I will replace all of them later this season, but for now this will do.

A hose, a bucket, some dish soap and an old car wash mit kept this little guy entertained for about 2 hours.