sydngoose

Well-known member

Hi all. I fish by myself a lot, so a windlass was needed to fascilitate deeper water anchor retrieval. Lewmar's profish 700 freefall function was important to me. After reading and researching the windlass install, I followed Lewmars instructions including "for optimal performance, the rode should drop directly over the deepest part of the anchor locker". This project would have been easier if I mounted the unit on the back of the pulpit, but I needed 330 feet of rope and 25 feet of chain and did not want any binding up deploying or retrieving. I built a pod for the windlass, reinforced beneath the deck with a backing plate, fabricated a "squish plate" and used cabosil and epoxy to make it one body, part of the hull.

A special THANK YOU to GrouperJim and Bobby for the inspiration and pictures to help me identify where and how I wanted this installation to occur. Here's the project almost complete:

1st step was to cut the phalange away from the current anchor locker to allow a direct mounting of the backing plate, squish plate and windlass "pod".

and this is what I was left with:

The, I had to construct the pod itself: I used the factory anchor locker hatch as a template and cut (4) pieces from 3/4 inch marine plywood, used RAKA epoxy to laminate them all together, then faired it all in with cabosil/ microballoons/ epoxy thickened to "mayonnaise" consistentcy. The pod ended up being 3 and 1/4 inches thick:

the next image demonstrates the "backing plate" and "squish plate" how it will be presented below and on the deck. These were cut out of 3/4 inch marine ply as well and encapsulated with thickened RAKA epoxy. You can see how much the backing plate will extend BELOW the deck: it was epoxied to the beneath side of the deck, then the squish plate epoxied on top of the backing plate.

backing plate epoxied into place:

In this next image, you'll see the backing plate secured/ epoxied into the hull, the "squish plate" epoxied to the backing plate. The template provided by Lewmar was used to cut my initial holes to accept the windlass:

Look how thick the pod cut out was (3inch hole saw) for the rode:

The inside rode hole (3 inch diameter) was coated with thickened epoxy to make water tight and add some rigidity incase the chain rubbed the inside of the bored hole:

I used "Petit easypoxy" paint in "sandstone" to give the pod some parker like color blend. I then epoxied the pod to the "squish plate" and faired in the sides.

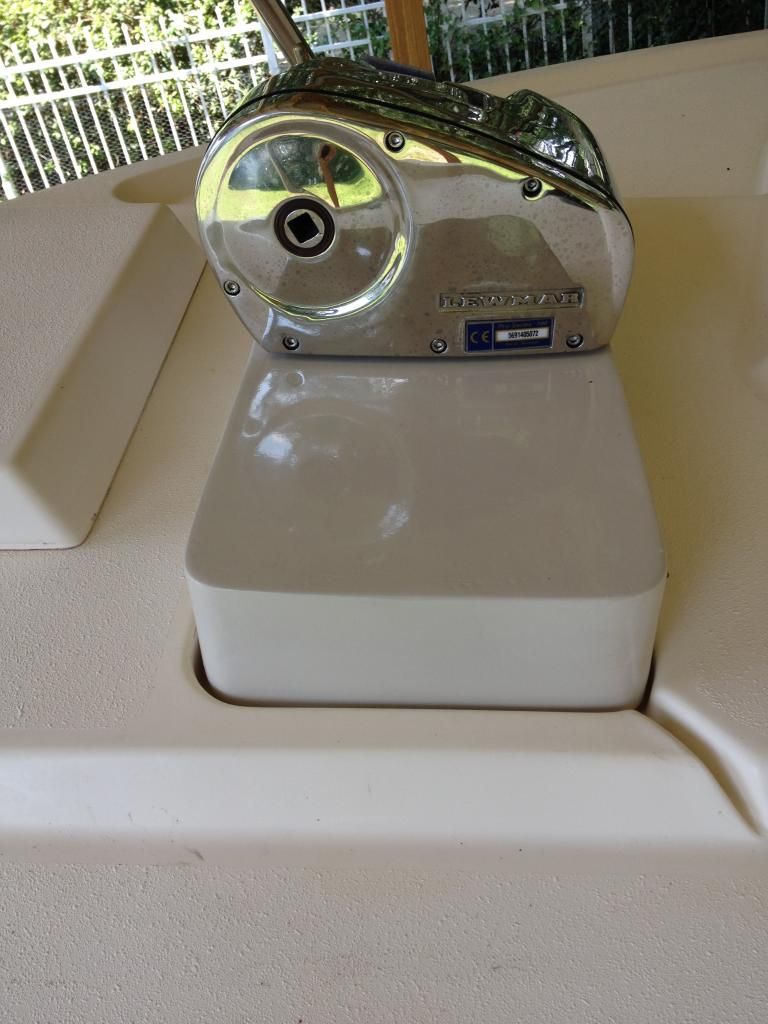

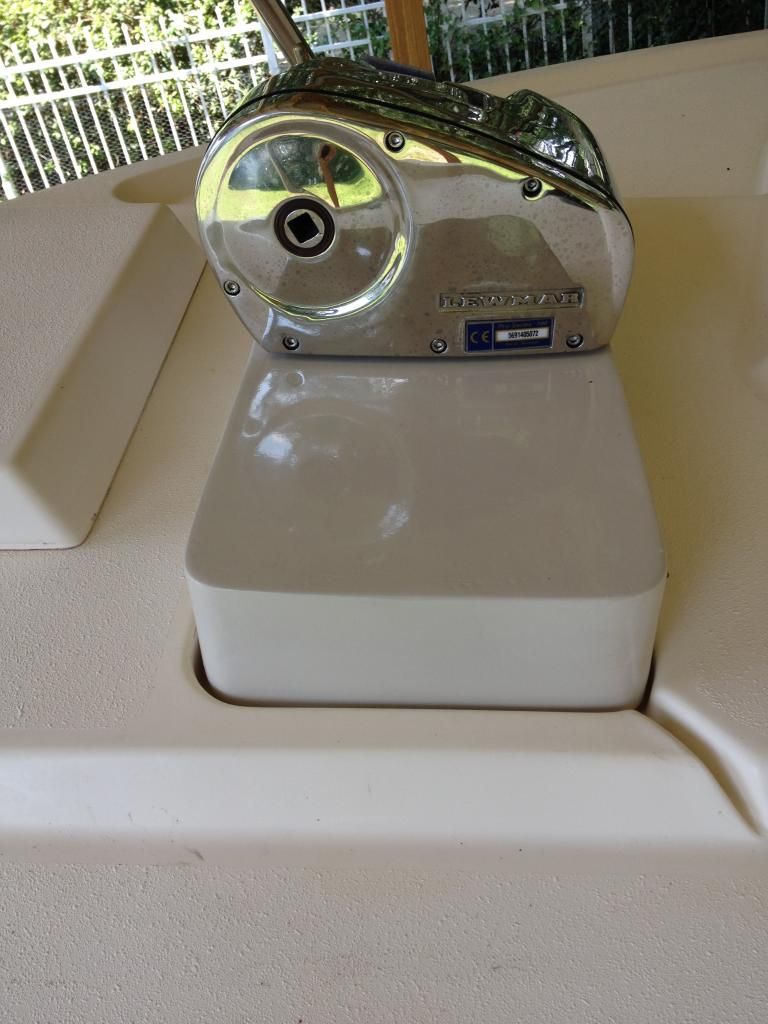

Then I used 4200 Fast cure to back fill the bolt holes, the wiring holes and a small lip around the rode hole where the windlass gasket sits. Windlass applied:

Then the rode was loaded into the windlass down into the locker. I talked to Lewmar tech support and was instructed to soak the new Lewmar 8 plait rode in fresh water for 48 hours before initial loading, so I did.

So, I got 331 feet of 8 plait rope with 25 feet of spliced G4 high test chain attached via swivel to the delta plow 14 anchor.

Still to do: a.) chain stopped attached mid' pulpit b.) parachord redundant chain stopper applied from cleat to chain. c.) gel coat fill in the previous screw holes where hinges were located for factory locker hatch.

All wiring was done with utmost care and independent electrical system from anything else in the boat. Circuit breaker placed at the battery, and I did program in the radio receiver and the 3 switch remote control (which is SUPER sweet)! I was pleased to see there was TONS more room in the anchor locker for more rode, but currently there is 356 feet available to use.

See you out there!

A special THANK YOU to GrouperJim and Bobby for the inspiration and pictures to help me identify where and how I wanted this installation to occur. Here's the project almost complete:

1st step was to cut the phalange away from the current anchor locker to allow a direct mounting of the backing plate, squish plate and windlass "pod".

and this is what I was left with:

The, I had to construct the pod itself: I used the factory anchor locker hatch as a template and cut (4) pieces from 3/4 inch marine plywood, used RAKA epoxy to laminate them all together, then faired it all in with cabosil/ microballoons/ epoxy thickened to "mayonnaise" consistentcy. The pod ended up being 3 and 1/4 inches thick:

the next image demonstrates the "backing plate" and "squish plate" how it will be presented below and on the deck. These were cut out of 3/4 inch marine ply as well and encapsulated with thickened RAKA epoxy. You can see how much the backing plate will extend BELOW the deck: it was epoxied to the beneath side of the deck, then the squish plate epoxied on top of the backing plate.

backing plate epoxied into place:

In this next image, you'll see the backing plate secured/ epoxied into the hull, the "squish plate" epoxied to the backing plate. The template provided by Lewmar was used to cut my initial holes to accept the windlass:

Look how thick the pod cut out was (3inch hole saw) for the rode:

The inside rode hole (3 inch diameter) was coated with thickened epoxy to make water tight and add some rigidity incase the chain rubbed the inside of the bored hole:

I used "Petit easypoxy" paint in "sandstone" to give the pod some parker like color blend. I then epoxied the pod to the "squish plate" and faired in the sides.

Then I used 4200 Fast cure to back fill the bolt holes, the wiring holes and a small lip around the rode hole where the windlass gasket sits. Windlass applied:

Then the rode was loaded into the windlass down into the locker. I talked to Lewmar tech support and was instructed to soak the new Lewmar 8 plait rode in fresh water for 48 hours before initial loading, so I did.

So, I got 331 feet of 8 plait rope with 25 feet of spliced G4 high test chain attached via swivel to the delta plow 14 anchor.

Still to do: a.) chain stopped attached mid' pulpit b.) parachord redundant chain stopper applied from cleat to chain. c.) gel coat fill in the previous screw holes where hinges were located for factory locker hatch.

All wiring was done with utmost care and independent electrical system from anything else in the boat. Circuit breaker placed at the battery, and I did program in the radio receiver and the 3 switch remote control (which is SUPER sweet)! I was pleased to see there was TONS more room in the anchor locker for more rode, but currently there is 356 feet available to use.

See you out there!