Again, fellas, your kindness is warming to the soul. Baby Grace and momma are home, and we are transitioning now to a three children household…now, back to the mission at hand:

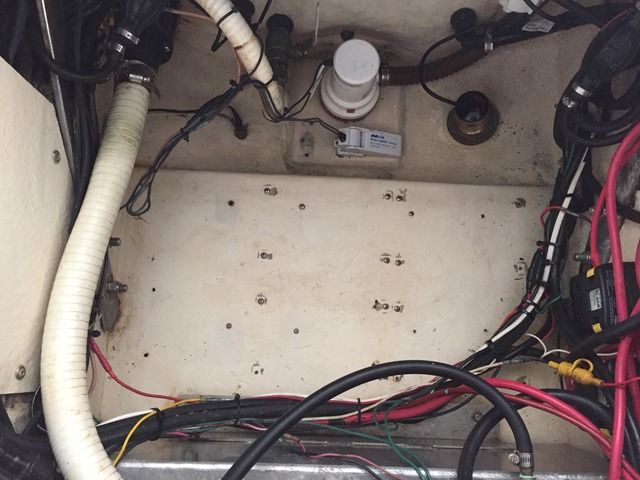

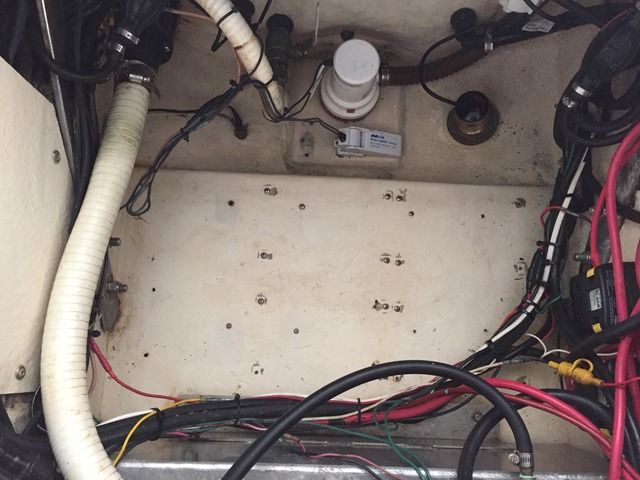

The three batteries were previously mounted in the bilge compartment on a "battery shelf". I have ALWAYS loathed batteries in the bilge for so many reason. The three batteries (2 cranking and 1 dedicated deep cycling house) were moved forward beneath the cabin in a "secret compartment", so I wanted to clean all the old screw holes in the bilge.

I ended up removing all the screws, back filling with UN-thickened injected epoxy resin, then fairing with formula 27 and rolled gel coat onto the tray: 3 coats.

Another priority for me was to have a cushion fabricated for the "galley drop down table" that spans the two benches: with a blanket and pillows, this makes for an amazing entertaining, play area for the children. I tested it out with my two oldest babies: Jack and Samantha. They gave two thumbs up.

As promised, here are the completion pictures of the forward cabin window covers to keep the N/NE sunlight out of the cabin. Pleased with results, though "linen" sunbrella color would have POPPED…but, still happy with the gel white.

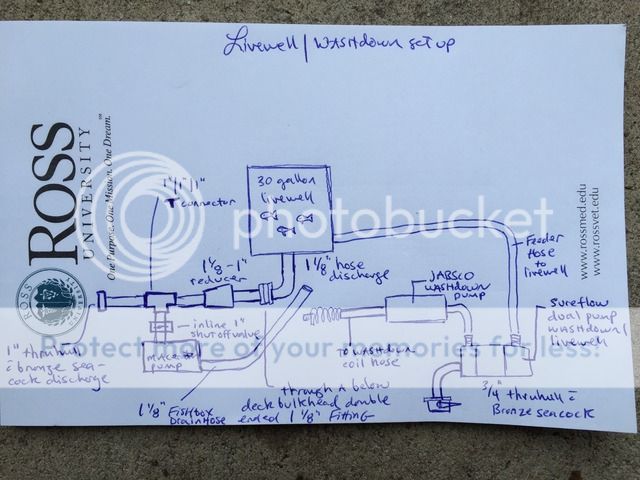

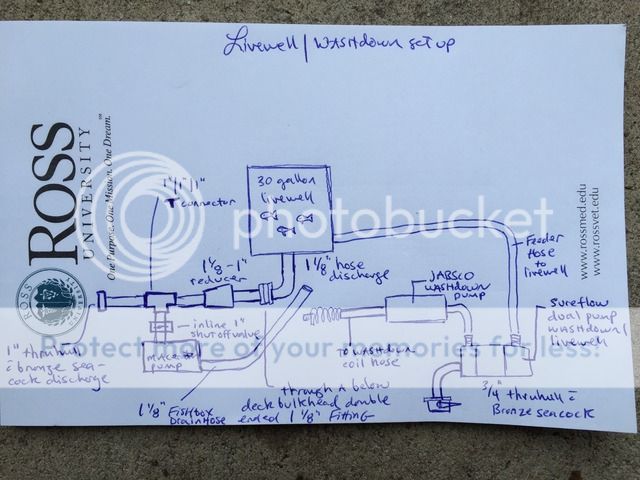

Finally, I need some input on my live well schematic. What do you guys think of this plan? Any inherent concerns recognized? I'll be plumbing and installing this live well this week.