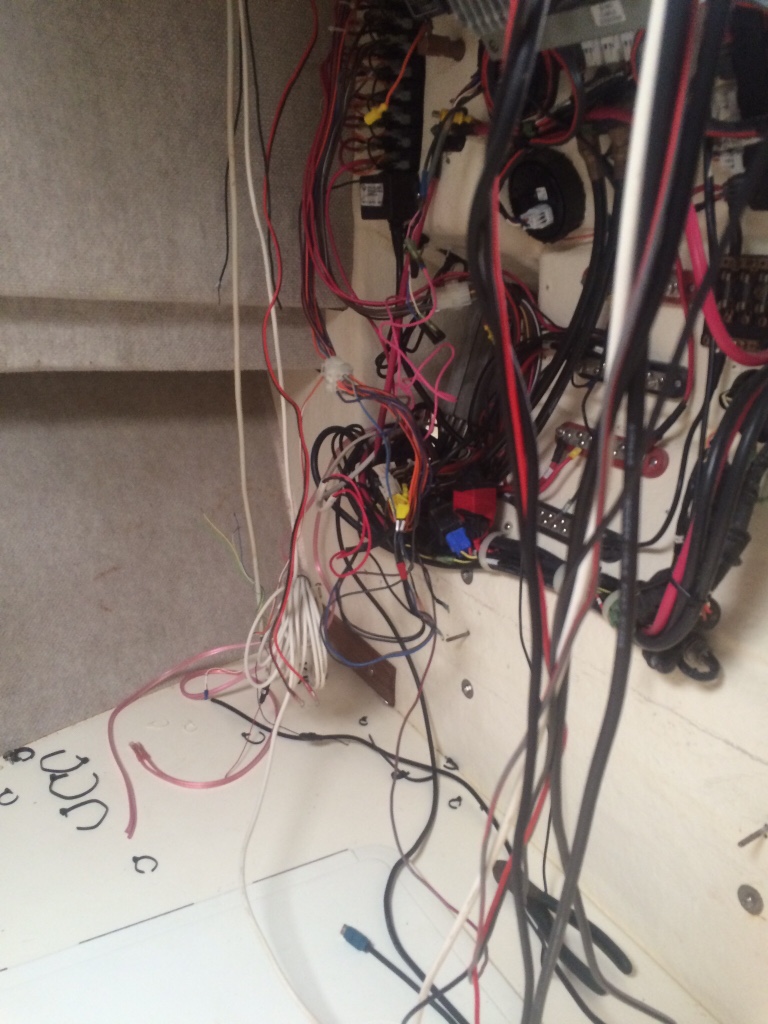

not to good with the posting and picture thing sorry guys I'm trying. this all started out buy wanting bigger tabs and under water lights ! than i stated looking at all wires stuffed in the starboard battery box . it was stuffed 3 battery switches 2 40a breakers yamaha bus rail for there wires and a 29r battery plus all rigging for both engines. so i doug in and pulled it all out i hard 2 24 group batteries in my bilge plus my battery charger 2 fuel filters , live well pump hoses and drains for it as well . port side box had a 29 group battery and my wash down pump. Now its all empty no wires batteries or pumps !! going to clean all 3 areas counter sink all screw holes and fill with epoxy took off the had rail on both boxes and I'm going to learn how to fill the holes in the battery boxes. i will than have 3 new clean canvas to work with. i also took off the back of my helm area to get in to that part of all my electrical found lots of lose connections so i pulled out the factory wires from the switch panel to the bilge it has to plugs in it one was bad and than a few crimps from install of all pumps

my new plan is to have one 4d house battery 2 staring batteries with a bep 3 battery bank cluster ( thanks to warthog5 )

all new wires and connections

starboard side battery box will only have the starboard motor wires and battery plus a JL audio 8.8 speaker in it bilge will have the new bep switches in there with the house battery and under water lights junction box live well pump and so on

port side box 1 starting battery and wires for that motor and a wash down pump plus speaker

wondering why parker spilt my switch panel into 2 parts and made it have 2 40a breakers?

going to run all new wires from switch to each pump or light no more breaks in the line

and just out right clean it all up so maybe it will look like a CABO wire job lol i hope also replacing all shifter and throttle cables

well i have lots to learn i never did and fiberglass work so we'll see

looking forward to seeing what all have to say thanks guys and ill post pics as i remember and work on it