Want It to last? Want it to look good down the road?

3/8in Plywood with a 6oz covering of fiberglass and fill the weave. Why add the fiberglass?

Because plywood will "Check". What is checking? Checking is when the grain of the plywood open up from heat, Cold and weathering.

Coating will just epoxy will not prevent this....Especially on Fir plywood. [Which is the Standard for marine plywood.]

Here is a experiment that I did many..many years ago.

At first look it appears the the paint is failing....It did not, but the exterior ply of the A-B Marine fir plywood did. Wooden boats have this same problem.

The framing is Lodge Pole...2 X 4 ripped down and dado for the plywood....All surfaces were covered with epoxy resign....Then primed with Awlgrip 545. it was top coated with PPG Concept.

It's been put in the weather for Years....without any attention.

I'd suggest that you cut all your panels.. Then glass them with either 4oz or 6oz glass....Easy to do when they are laying flat. [both sides] Then assemble the box....good time to practice [Stitch & Glue] technique.

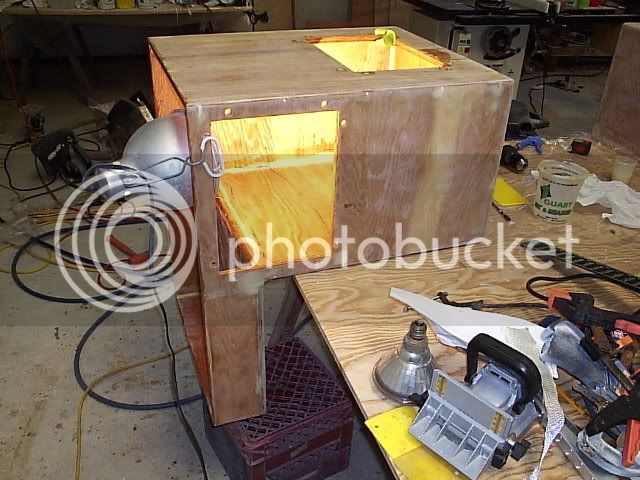

Here's some examples.

These were the seat box's in my mako.

Yes it is all covered with glass. The holes predrilled larger and backfilled with epoxy/cabisol. No chance of water ever coming in contact with the wood.

Attached to deck with alum angle

Finished.

These were painted with Awlgrip and looked as good the day the boat was sold, as they did the day they were completed.