Here's the result after changing out the factory 12x12 Lenco tabs for 12x18's

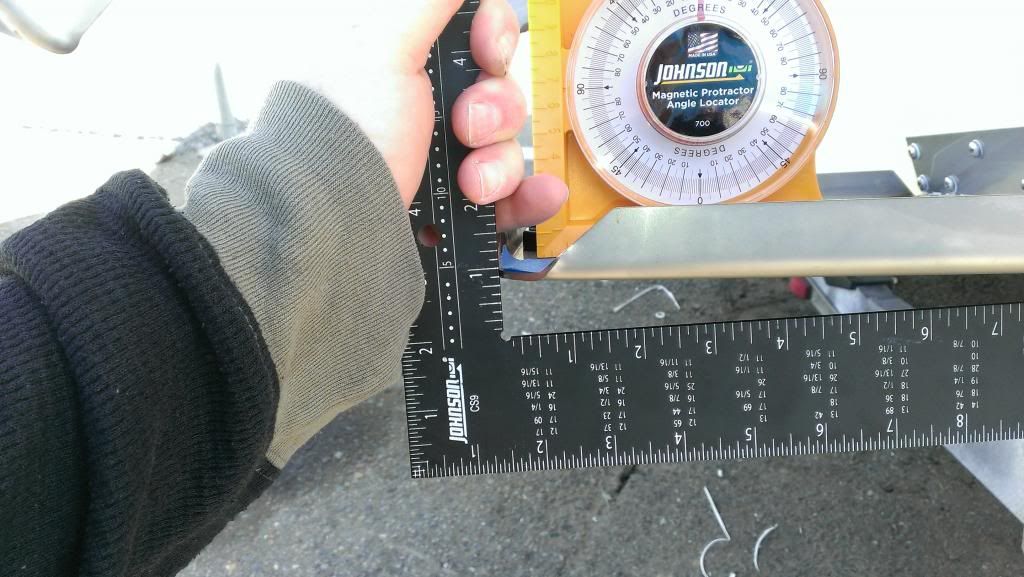

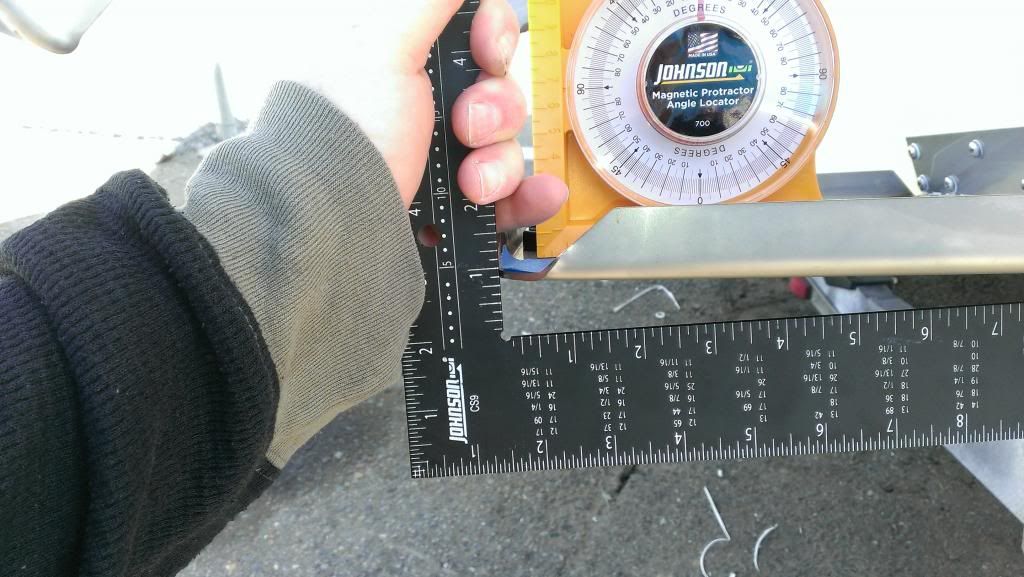

Full up position, reads 2degress from level - the boat is sitting bow high with trailer tongue jack raised

full down reads ~18 degreees, so I have a little over 15degrees total travel.

trailing edge is 7/8" above plane from bottom of hull. Since I didn't move the original position of

the actuators, the full up/down positions are same as I had with factory 12x12 tabs.

My boat always liked to have a touch of down-tab with the factory tabs. In slow travel into head-seas, I was

always looking for a little more down-tab. The new, wider blades should help give me more lift when deployed, but still wondering

if I could add a little shim to give me more usable range to the down-side. A 1/4" piece of starboard between

bottom of actuator and tab might dial in a full 20degreess downtab and I'd only lose a couple of degrees negative trim that

never really did me any good - even in heavy following seas. Will give a sea trial and see how she handles first...

(wondering now too if I had just added shims to the original 12x12's if that would have been "good enough" of an upgrade...)

To get the new 12x18 tabs, I bought a new, full kit to also get the indicator switch upgrade. I have a spare set of actuators now.

rear view1

rear view 2

I did the "lazy lenco" upgrade option leaving the actuators in the original position. But needed

to drill new holes in the tab to bolt the actuators to the tab in an offset position. Original tab holes filled with JB weld, also added a zinc.

Full up position, reads 2degress from level - the boat is sitting bow high with trailer tongue jack raised

full down reads ~18 degreees, so I have a little over 15degrees total travel.

trailing edge is 7/8" above plane from bottom of hull. Since I didn't move the original position of

the actuators, the full up/down positions are same as I had with factory 12x12 tabs.

My boat always liked to have a touch of down-tab with the factory tabs. In slow travel into head-seas, I was

always looking for a little more down-tab. The new, wider blades should help give me more lift when deployed, but still wondering

if I could add a little shim to give me more usable range to the down-side. A 1/4" piece of starboard between

bottom of actuator and tab might dial in a full 20degreess downtab and I'd only lose a couple of degrees negative trim that

never really did me any good - even in heavy following seas. Will give a sea trial and see how she handles first...

(wondering now too if I had just added shims to the original 12x12's if that would have been "good enough" of an upgrade...)

To get the new 12x18 tabs, I bought a new, full kit to also get the indicator switch upgrade. I have a spare set of actuators now.

rear view1

rear view 2

I did the "lazy lenco" upgrade option leaving the actuators in the original position. But needed

to drill new holes in the tab to bolt the actuators to the tab in an offset position. Original tab holes filled with JB weld, also added a zinc.