SBH2OMan

Well-known member

Based on another thread, I've decided to post my learnings so far about the OX66 motor on the Lori-K so that it might benefit other Parker owners with similar engines (or those considering buying a Parker with one of these motors). This is in no particular order, and I'll probably update it as I learn more about the motor. I will reference sources where possible. If sources are excluded, you can assume that the learning is from my own first-hand experience. I have a lot of experience wrenching on automotive and motorcycle engines (including complete rebuilds), but this is my first foray into outboard engines...

First, if I was considering buying a boat with one of these motors, I would do the following:

1. Disregard hours on the clock unless excessively high (over 1000) or low (under a few hundred). If well maintained, these seem to have a very good reputation for longevity.

2. Compression check. Don't worry if "low" (high 90's) unless the rest are in the 120's. As long as they are all close (10%) you are golden. According to a certified Master Yamaha Technician, "typicaly the 3.1,especially units produced after 2003, run about 85 PSI on a compression test but Yamaha does NOT post any specifications for compression."

3. Check idle speed. When warm should be 700 to 800 (730 +/- 30 RPM according to my manual). I idling at 1100 you have a problem with a sensor and the engine going into "fault mode" where it locks timing at 7degrees BTDC and idle at 1100. Check WOT - results can indicate the type of sensor problem

4. If you can buy or borrow them, get a "winky blinky" test lamp for reading the fault codes, also get a test harness for testing the TPS and O2 sensor. According to same certified Master Tech:

These test procedures are outlined in section 8 (electrical) of the Yamaha service manual.

I paid a certified Yamaha mechanic to inspect he engine, he charged me $300 and didn't do any of these simple things other than the comp test. I learned these simple things AFTER buying and wrenching on this motor.

When I trialed the boat, I noticed the high idle, and unfortunately just believed the broker when he said "its a simple adjustment - just a couple of screws". As it turns out, it is a very important indicator of other problems - probably easy to fix, but problems nonetheless.

Procedures for testing and cleaning the O2 sensor (a critical component of this engine - probably THE most critical one):

http://www.boatsetup.com/O2sensor.pdf

If the Oxygen density sensor is giving faulty readings, it will tell the fuel system to lean or richen the mixture and it can lead to disastrous consequences.

Other things:

1. Changing out the Low Pressure Fuel Pumps is within the capabilities of any person that knows how to operate a socket wrench. It only requires a 10mm socket. The only trick is that you need to loosen the high pressure fuel pump assembly to get to one of the bolts on the middle pump (there are three).

2. If you have a 1999 OX66 in a 225 or 250 (and perhaps others) specifically an S250TXRX - BE CAREFUL about which VST filter and gasket you purchase. I recommend pulling opening up the VST tank and inspecting it before ordering, because 1/2 of the parts guides (including the one at SIM Yamaha) are WRONG and you will get the incorrect parts. The proper one for my motor is the 66k series part and is about $45 but the one that SIM sent me based on my model number was the 65L series and was $85! I did not think there was a problem until I tried to install the gasket and found that it was really not the same (I just assumed that the filter had been "updated" to a new and improved version, but I was wrong). The correct one for my motor is clear (tan after being used) and the WRONG one was blue.

-Brent

First, if I was considering buying a boat with one of these motors, I would do the following:

1. Disregard hours on the clock unless excessively high (over 1000) or low (under a few hundred). If well maintained, these seem to have a very good reputation for longevity.

2. Compression check. Don't worry if "low" (high 90's) unless the rest are in the 120's. As long as they are all close (10%) you are golden. According to a certified Master Yamaha Technician, "typicaly the 3.1,especially units produced after 2003, run about 85 PSI on a compression test but Yamaha does NOT post any specifications for compression."

3. Check idle speed. When warm should be 700 to 800 (730 +/- 30 RPM according to my manual). I idling at 1100 you have a problem with a sensor and the engine going into "fault mode" where it locks timing at 7degrees BTDC and idle at 1100. Check WOT - results can indicate the type of sensor problem

4. If you can buy or borrow them, get a "winky blinky" test lamp for reading the fault codes, also get a test harness for testing the TPS and O2 sensor. According to same certified Master Tech:

"no codes no faults.

the exception is the O2 sensor which has NO codes associated with it.

when cold,below about 113*F, that motor will idle about 1100-1200 RPM.

code 33 will be flashing.

once warm the RPM will drop to the designated idle speed and code 1 will be displayed if everything is happy.

if the CTS [coolant temp sensor] fails or becomes unplugged the system will set code 13 unless its an in range failure.

lets say the CTS is ALWAYS telling the ECU [electronic control unit] that the engine is at 90*F.

guess what that dumbass ECU is gonna do.

its gonna fix fuel rich at low speed,fix idle timing at 7* BTDC.

idle speed will remain about 1100 RPM and top speed CAN be reached.

unplug the Knock sensor or the TPS [throttle position sensor].

stupid ECU is gonna lock ign timing at 7* BTDC,fix fuel rich and idle speed will be about 1100 and top speed CANNOT be reached."

These test procedures are outlined in section 8 (electrical) of the Yamaha service manual.

I paid a certified Yamaha mechanic to inspect he engine, he charged me $300 and didn't do any of these simple things other than the comp test. I learned these simple things AFTER buying and wrenching on this motor.

When I trialed the boat, I noticed the high idle, and unfortunately just believed the broker when he said "its a simple adjustment - just a couple of screws". As it turns out, it is a very important indicator of other problems - probably easy to fix, but problems nonetheless.

Procedures for testing and cleaning the O2 sensor (a critical component of this engine - probably THE most critical one):

http://www.boatsetup.com/O2sensor.pdf

If the Oxygen density sensor is giving faulty readings, it will tell the fuel system to lean or richen the mixture and it can lead to disastrous consequences.

Other things:

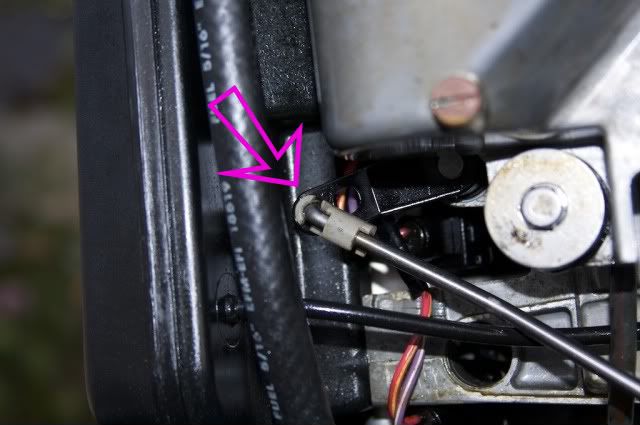

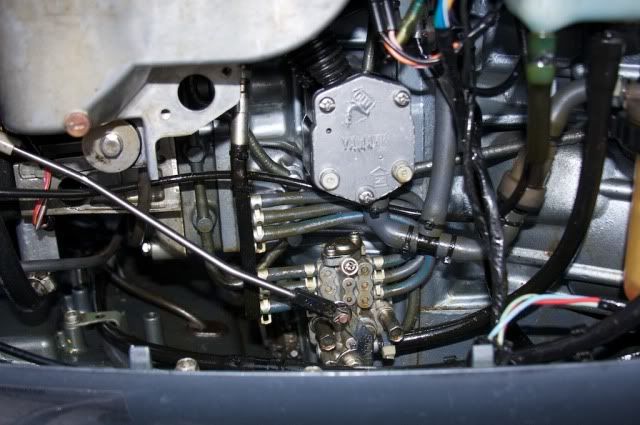

1. Changing out the Low Pressure Fuel Pumps is within the capabilities of any person that knows how to operate a socket wrench. It only requires a 10mm socket. The only trick is that you need to loosen the high pressure fuel pump assembly to get to one of the bolts on the middle pump (there are three).

2. If you have a 1999 OX66 in a 225 or 250 (and perhaps others) specifically an S250TXRX - BE CAREFUL about which VST filter and gasket you purchase. I recommend pulling opening up the VST tank and inspecting it before ordering, because 1/2 of the parts guides (including the one at SIM Yamaha) are WRONG and you will get the incorrect parts. The proper one for my motor is the 66k series part and is about $45 but the one that SIM sent me based on my model number was the 65L series and was $85! I did not think there was a problem until I tried to install the gasket and found that it was really not the same (I just assumed that the filter had been "updated" to a new and improved version, but I was wrong). The correct one for my motor is clear (tan after being used) and the WRONG one was blue.

-Brent